Welcome To

Vermont Technologies Pvt. Ltd.

-

20years of experience in

the Oil & Gas industry -

15000Flow Metering unit

across globe till date

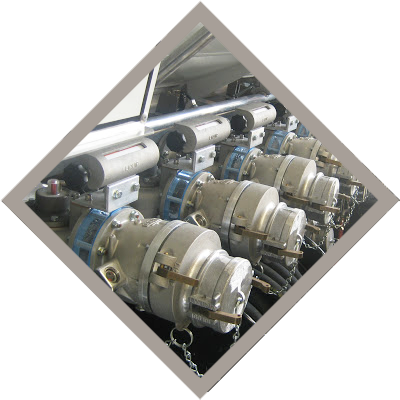

Focused in Supply of Products & Services for Petroleum Distribution Industry

Our Products

Quality With Dedication

Vermont Technologies provides solution to wide range of metering Applications.

Vermont Technologies has supplied over 16000 Flowmetering units across the globe till date.

Based on our field experience with metering Installation, we can offer you a complete and customised service.