We are Manufacturer, Supplier, Exporter, Services Provider of Piston Digital Control Valves and our setup is situated in Pune, Maharashtra, India.

Alma Piston Digital Control Valve is a piston type valve, designed primarily for digital control of loading rack application. It is an electrically actuated, hydraulically operated multi-function valve. When used with a flow meter and an electronic batch controller, it can perform local as well as remote controlled precision batching operations. The Piston Digital Control Valve also offers an in-built flow governing function, when used with an electronic batch controller.The Alma Piston Digital Control Valve works on the principle of "balanced piston".

Piston is always exposed to high upstream pressure from its bottom side, whereas pressure in the piston chamber can be varied with the help of solenoid valves. When pressure in the piston chamber is equal to the high upstream pressure, the top spring acts as a differential force, pushing the piston down on the valve seat and the valve is held tightly-closed.

When pressure in the piston chamber is relieved with the help of solenoid valves, a differential pressure is created across the piston. The high upstream pressure below the piston overcomes the top pressure plus the spring force and pushes the piston up, resulting in valve opening and the flow starts.

- Fail-safe design : the valve is held closed upon loss of electric supply and/or line pressure

- Positive shut-off : meets ANSI Class VI for bubbletight closure

- Multi-stage opening and closing : avoids static charge generation due to splashing of product in the beginning and foaming / overflow at the end, resulting in accurate delivery

- Low pressure drop

- Rectangular ports : for uniform valve response and linear control

- Built-in flow rate control : no need of external pilots for flow rate control, when used with electronic batch controller

- No diaphragm

The Alma Piston Digital Control Valve basically consists of a spring loaded piston, sliding in the guide liner, and two solenoid valves. Piston chamber formed between the liner and the piston top, is connected to the upstream and downstream pressures by normally open (NO) and normally closed (NC) solenoid valves respectively.

When the Piston Digital Control Valve is used with an electronic batch controller, it can be digitally controlled by operating the solenoid valves through any of these three stages :

- When NO and NC solenoids are energised, the valve opens gradually.

- When NO solenoid is de-energised (keeping NO solenoid energised), the valve locks at its current position.

- When NO and NC solenoids are de-energised, the valve closes gradually.

- The Piston Digital Control Valve can be supplied with external stem and limit switches. Signals from the switches can be used monitor the flow rate(s) and/or to indicate the valve position - open or closed.

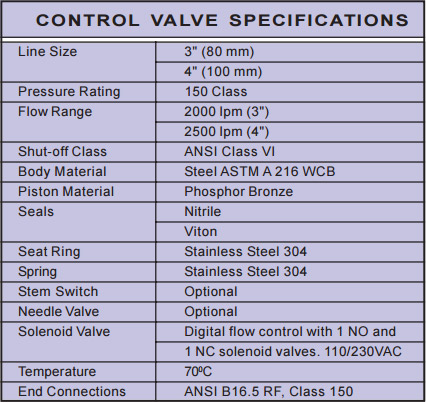

- Standard valve is supplied with 230 V AC solenoids, other voltage solenoids can be supplied on request.